Understanding the Ratio Control Motor (Stepper Motor) in CVT Transmissions

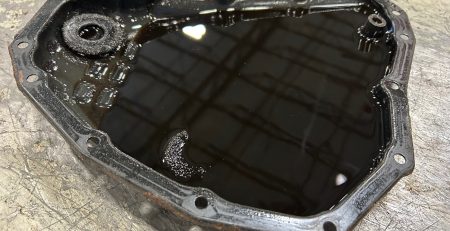

The Ratio Control Motor, commonly referred to as the “Stepper Motor,” plays a crucial role in the operation of early CVT1, CVT2, and CVT3 transmissions. However, as CVT technology advanced, later models such as the CVT7 and CVT8 moved away from the Stepper Motor design. Instead, these newer models rely on solenoid pressure to control the variators (pulleys), marking a shift in how ratio changes are managed within the transmission system.

How the Stepper Motor Works in CVT Systems

In models equipped with the Stepper Motor, the Transmission Control Module (TCM) manipulates the transmission ratio by controlling the motor’s steps. These steps are regulated by sending on/off signals to the motor’s four internal coils. The timing and pattern of these signals depend on various factors, such as engine load and road conditions.

As a result, the motor adjusts the flow of hydraulic pressure to the primary pulley, which is responsible for controlling the gear ratio. The secondary pulley pressure is handled separately, providing more refined control over the CVT’s performance.

P1777 Code: Electrical Failure in the Stepper Motor

One common issue associated with the Stepper Motor is the triggering of diagnostic trouble code (DTC) P1777. This code usually indicates an electrical failure or malfunction in the Stepper Motor circuit. When the TCM detects an abnormality, such as a lack of response or improper signals from the motor, it will store the P1777 code and often activate the Check Engine Light (CEL).

This error typically points to problems such as:

- Stepper Motor coil failures.

- Damaged or corroded wiring harnesses.

- Poor ground connections.

- Faulty TCM or incorrect signals sent to the motor.

When diagnosing a P1777 code, it’s essential to inspect the electrical connections and measure the coil outputs with a scan tool to ensure the motor is receiving the correct signals.

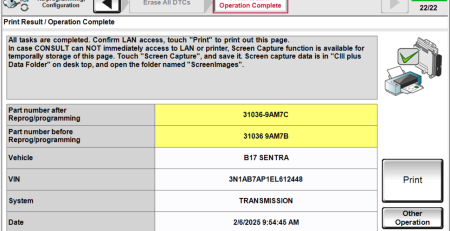

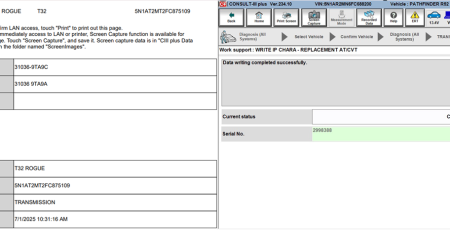

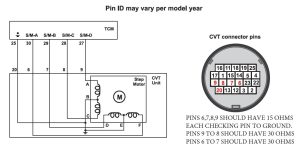

Stepper Motor Diagnostics Using Scan Tools

For skilled mechanics, diagnosing Stepper Motor issues related to the P1777 code can be straightforward using a capable scan tool, such as the Consult III Plus. You can measure the pulse width of the motor’s output signal within two seconds of ignition. The scan tool data provides the following pulse width outputs for each coil:

- Step Motor A: 30.0 milliseconds

- Step Motor B: 10.0 milliseconds

- Step Motor C: 30.0 milliseconds

- Step Motor D: 10.0 milliseconds

These measurements allow you to verify that the TCM is communicating correctly with the Stepper Motor and that the steps are being executed as expected. Discrepancies in these values could indicate issues with the motor itself, faulty wiring, or with the TCM’s signaling—often leading to the P1777 code.

Wiring and Grounding Considerations

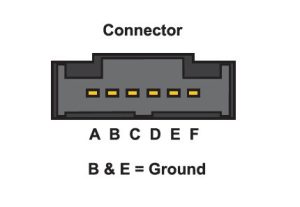

It’s critical to ensure that the motor’s wiring and connectors are functioning properly, especially when a P1777 code is present. The Stepper Motor is connected via a six-pin connector with the following pinout:

- A to F: Signal inputs and outputs

- B & E: Ground

Verifying proper grounding is essential, as any disruption can lead to incorrect motor operation or failure in controlling the CVT ratio. Poor ground connections can also trigger the P1777 code, indicating that the motor isn’t responding to TCM commands.

The Shift from Stepper Motors to Solenoids

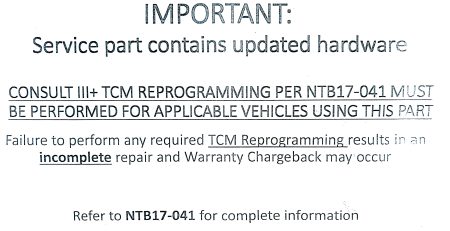

As the automotive industry progressed, Nissan transitioned from using Stepper Motors in CVTs to solenoid-based systems in later models (CVT7, CVT8). Solenoids offer a more efficient and responsive way to manage the flow of hydraulic pressure to the pulleys, eliminating the need for step-based motor control. In these newer systems, the solenoids directly regulate the pulley ratio, providing smoother and quicker adjustments that can improve overall transmission performance and durability.

Conclusion

For mechanics working on Nissan CVTs, understanding the differences between Stepper Motor and solenoid-based control systems is essential for accurate diagnostics and repairs. While older models equipped with the Stepper Motor require specific attention to pulse width, coil function, and troubleshooting DTC P1777, newer models have simplified ratio control with solenoid-based systems. Whether you’re working with a CVT1 or a CVT8, having the right diagnostic tools and a solid understanding of the system’s operation will ensure efficient and effective repairs.

For more information click on link below from Gears Magazine Article Titled:

Stop Wasting Money on Jatco CVT Stepper Motors

https://gearsmagazine.com/magazine/stop-wasting-money-on-jatco-cvt-stepper-motors/